Cookie Policy

Our site uses Cookies which are essential to provide site functionality, e.g. for logged in users and for standard Google analytics data which is normally anonymous. Such data allows us to improve our web site. We do not share any information with third party companies, nor do we collect any information which does not relate to our site.

"Our goal is to deliver the highest quality prototypes according to your schedule."

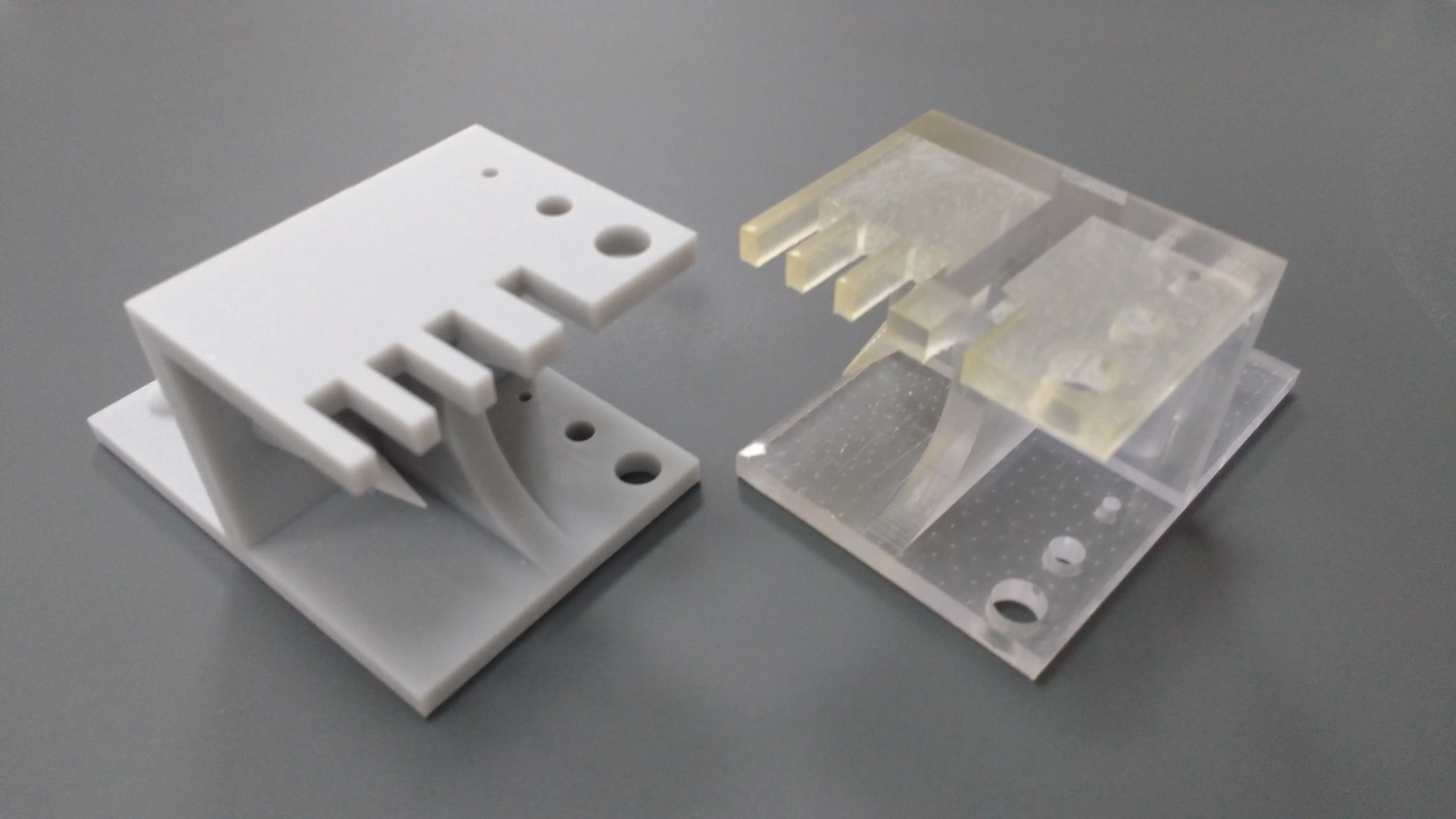

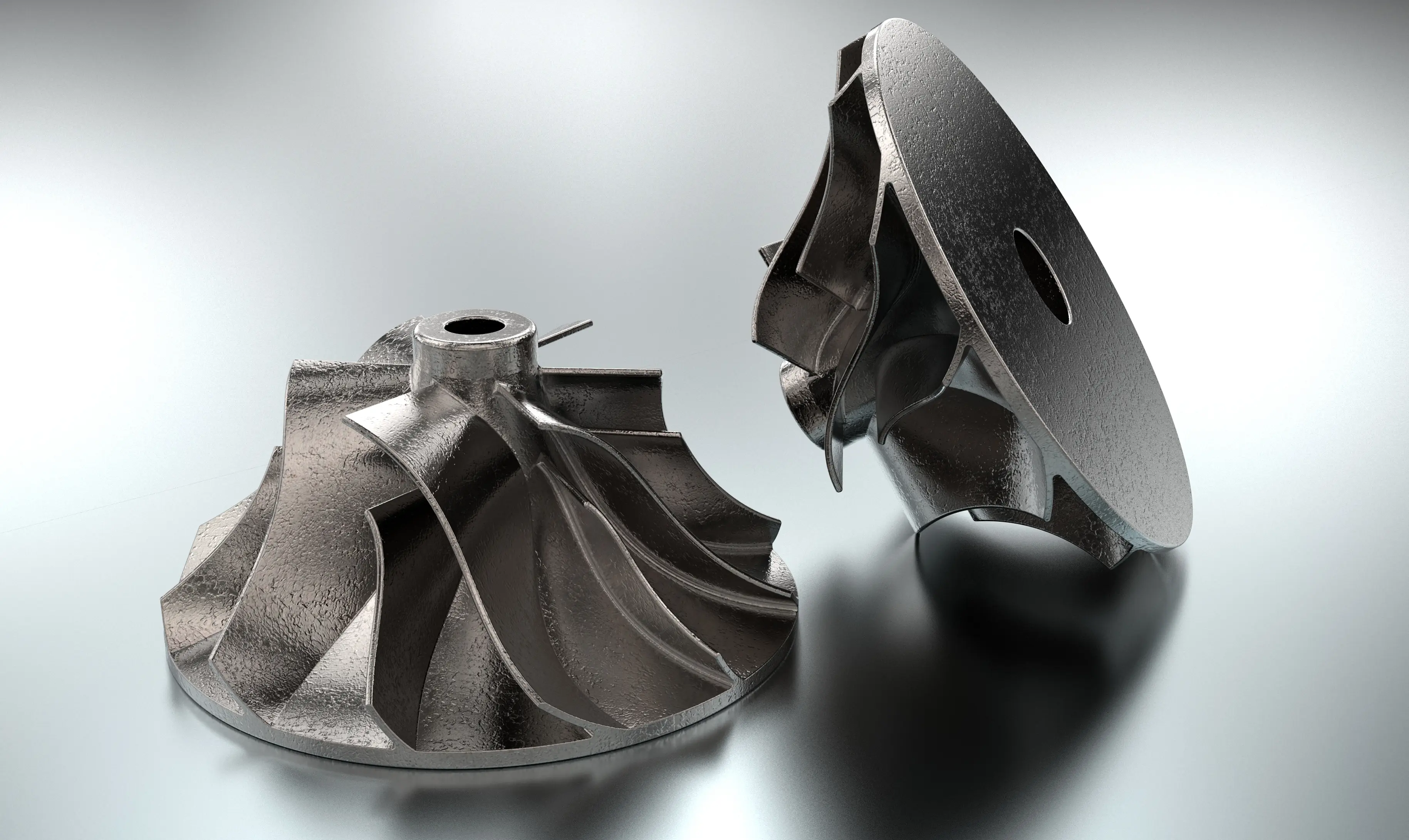

We will quote your requirements from a ‘one-off’ prototype to low and medium volume production quantities. , Aben Europe offers services that deliver customised parts which will be made to your quality and accuracy requirements.