Direct Metal Printing Services

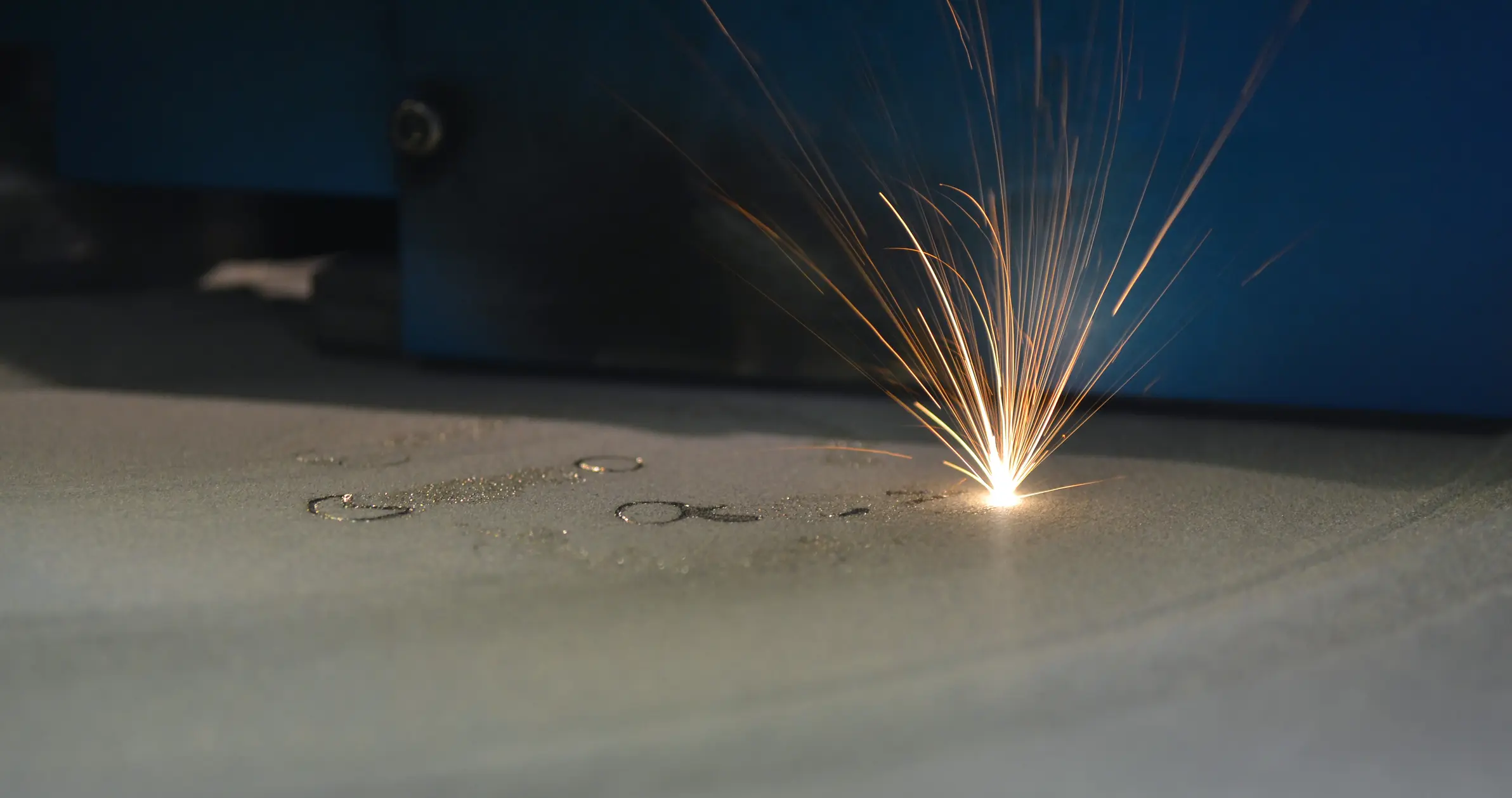

3D metal printing, also known as Direct Metal Laser Sintering (DMLS), metal additive manufacturing or Direct Meatal Printing (DMP) is revolutionising the way complex metal components are designed and produced. Unlike traditional manufacturing methods that often require molds, tooling, or extensive machining, DMP builds parts layer by layer directly from digital designs using fine metal powders and powerful lasers or electron beams. This process enables the creation of intricate geometries, lightweight structures, and highly customised parts that would be difficult or impossible to achieve with conventional techniques.

From aerospace and automotive to medical and industrial applications, DMP delivers strong, high-performance components with reduced material waste and shorter lead times. Its ability to rapidly prototype, customise, and manufacture end-use metal parts is reshaping industries, offering unprecedented design freedom and efficiency for today’s most demanding engineering challenges.

Unlike many 3D printing technologies, DMP can manufacture parts in materials which have a long history of service in engineering, such as stainless steel 316, or aluminium LM10. Aben Europe offers a wide range of materials, and large bodied metal sintering machines to help you achieve your manufacturing needs.

Material for DMP

The materials available for DMP parts supplied by Aben Europe:

Stainless steel 316

Nickel maraging steel 18Ni-300 tool steel

17-4 Martensitic stainless steel

Titanium Alloy Ti6Al4V

Aluminium

Inconel

Materials Machine Bed Size

| Machine Bed Size (mm) | ||

|---|---|---|

| 350x400x355 | 420x420x450 | |

| Stainless Steel 316 | - | ✓ |

| Aluminium | - | ✓ |

| Titanium | ✓ | - |

| Nickel Based Alloy | ✓ | - |

| Mould Steel 18Ni-300 | ✓ | - |

| 17-4 Maragsing Steel | ✓ | - |

Finishing of DMP Parts

The common route to part finishing is:

• Powder Removal: After printing, excess powder is manually removed from the part, often using brushes, compressed air, or vacuum systems.

• Support Removal: Parts are typically attached to the build plate with support structures, which are cut away using machining, wire EDM, or other mechanical means.

• Sanding and Grinding: Manual or machine sanding and grinding can be applied to smooth surfaces, especially in easily accessible areas.

Most parts are supplied after these three initial stages. However, depending the application of the pars, further finishing can be applied to them. These include:

| Finishes | Finish Definition |

|---|---|

| Heat Treatment | Parts undergo heat treatments (such as stress relief, aging, or annealing) to relieve internal stresses and improve mechanical properties. Advanced methods like Hot Isostatic Pressing (HIP) can further reduce porosity and enhance density. |

| Machining | Precision machining (milling, turning, drilling) is often used to achieve tight tolerances, refine critical surfaces, and improve overall dimensional accuracy. |

| Media Blasting | Techniques like glass bead blasting or sandblasting are used to deburr, clean, and create a uniform matte or satin finish on the part’s surface. |

| Tumble/Vibratory Finishing | These methods use abrasive media in a tumbling or vibrating chamber to smooth and polish the part, often used for batch processing. |

| Chemical Treatments | Etching, passivation, or chemical polishing can remove impurities, improve corrosion resistance, or create specific surface textures. |

| Electropolishing | An electrochemical process that smooths and brightens the surface, reducing roughness and enhancing appearance. |

| Plating | Electroplating can deposit a thin layer of another metal (such as gold, silver, or nickel) to improve appearance, wear resistance, or corrosion protection. |

| Thread Finishing | Threads can be printed, tapped, or chased with a tap for better fit and function. |

The choice of finishing method depends on the part’s application, required surface finish, dimensional tolerances, and material. Some methods, like extensive polishing or chemical treatments, may alter part dimensions, so these trade-offs must be considered during process selection.

Applications of DMP

DMP has a wide and rapidly expanding range of applications across multiple industries. Its key advantages include the ability to produce complex geometries, reduce production times, enable customization, and eliminate the need for traditional tooling. Below are the major application areas, supported by recent case studies and industry reports:

Functional Prototypes

Custom Tools and End-of-Arm Tooling

Complex Bracketry and Lightweight Components

Low-Volume and Specialty Parts

Medical and Dental Implants

Aerospace and Automotive Components

Electronics and Robotics

Jewelry

Oil and Gas Industry

DMP provides adidtional benefits of:

• Component Consolidation: Ability to combine multiple parts into a single printed component, reducing assembly time and potential failure points.

• Customization: Efficient production of individualized products, from medical implants to bespoke tools.

• Reduced Production Time and Costs: Especially for complex or low-volume parts, DMP can dramatically shorten lead times and lower costs compared to traditional machining.

3D metal printing continues to transform manufacturing by enabling designs and applications that were previously impossible or uneconomical with conventional methods

Example: Benefits of Manufacturing using DMP

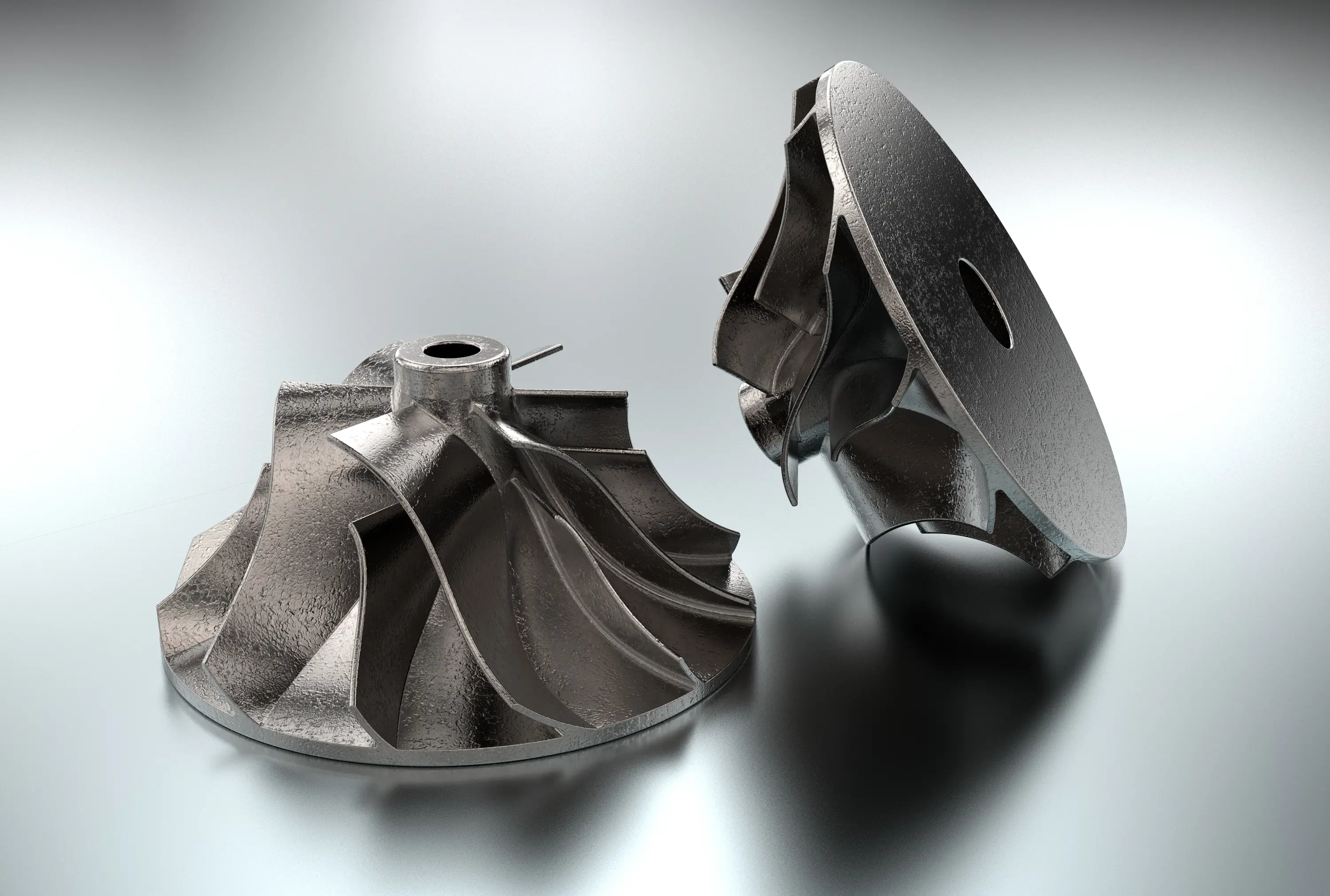

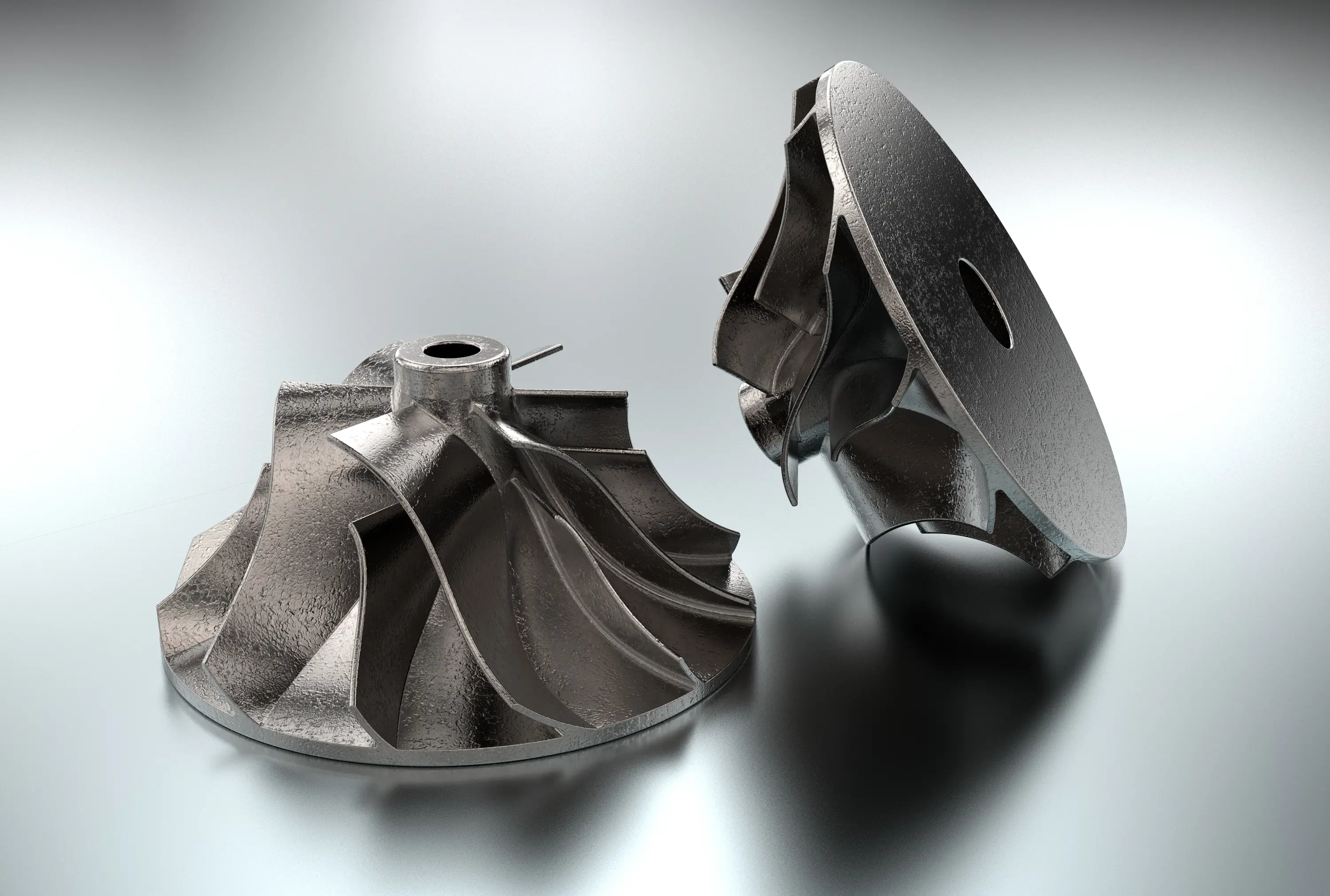

Turbo-Impeller Example

Let’s use the example of manufacturing a turbo-charger compressor wheel as a method of looking at the benefits of DMP for component manufacture. DMP offers significant advantages over traditional methods, particularly in performance optimisation, design flexibility, and production efficiency.

The key benefits include:

1) Weight Reduction and Performance Enhancement

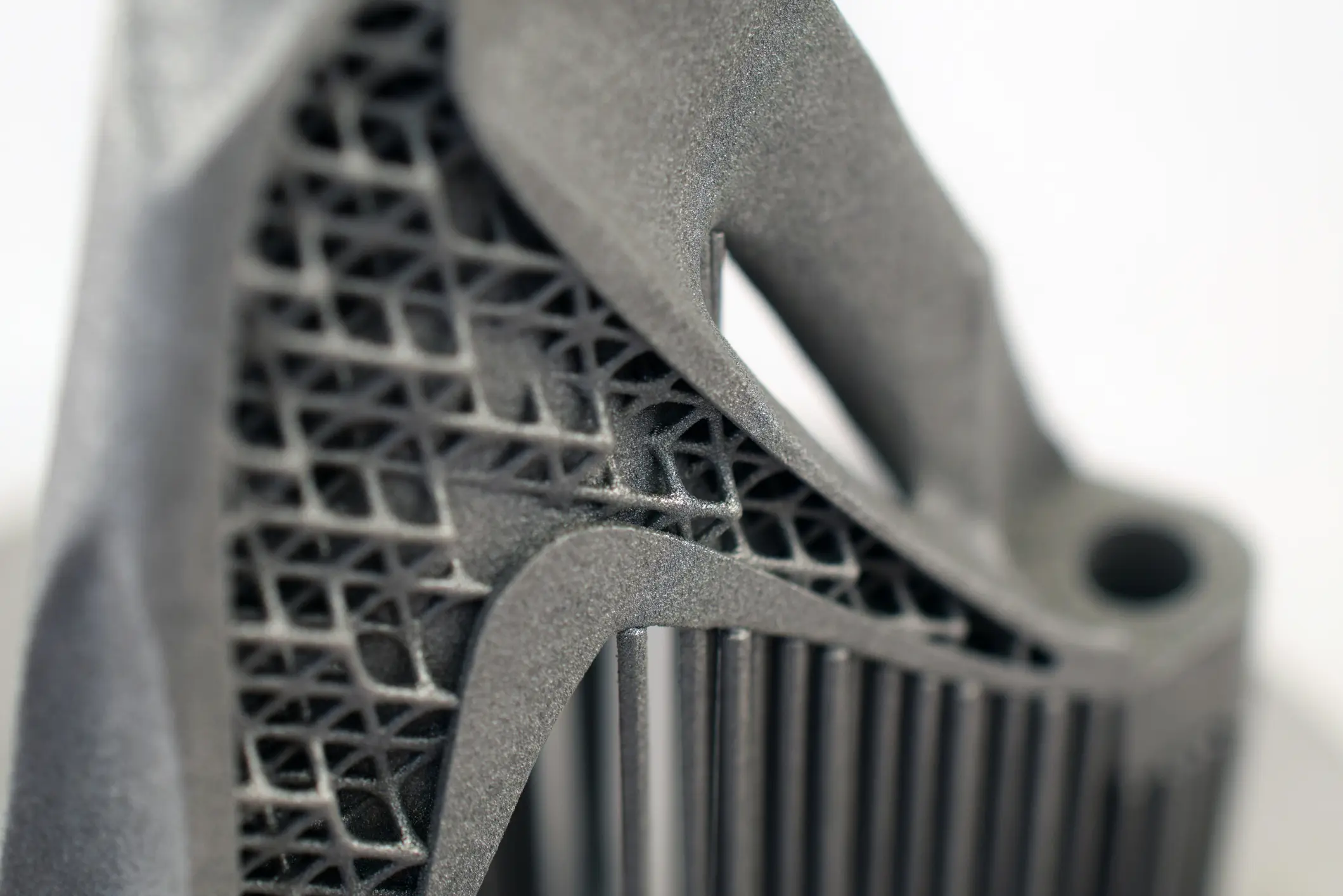

Metal 3D printing enables the creation of hollow or lattice structures that reduce part weight without compromising strength. For compressor wheels, this lowers rotational inertia, allowing faster response and improved efficiency. Optimised geometries also distribute stress more evenly, extending component lifespan.

2) Design Freedom and Complexity

Unlike subtractive methods, 3D printing can produce complex internal features (e.g., custom cooling channels, aerodynamic curves) impossible to machine conventionally. This permits topology-optimized designs that maximize airflow efficiency in compressor wheels while maintaining structural integrity.

3) Material and Cost Efficiency

• Reduced waste: Additive processes use only necessary material, critical for expensive alloys like titanium or Inconel, achieving up to 90% material utilization vs. ≤10° in machining.

• Lower tooling costs: Eliminates molds/fixtures, making low-volume production economically viable.

• Cost consistency: Per-part costs remain stable regardless of batch size, ideal for prototyping or small batches.

4) Accelerated Production Workflow

• Rapid iteration: Design changes require no retooling, shortening R&D cycles by weeks.

• Supply chain resilience: On-demand production reduces inventory needs and mitigates logistics delays.

• Automated fabrication: Minimal supervision needed during printing, freeing resources for revenue-generating tasks.

5) Case-Specific Advantages for Compressor Wheels

In turbocharger applications, DMP compressor wheels demonstrate:

• Corrosion resistance: Stainless steel options withstand moisture exposure during compression.

• Precision post-processing: CNC-machined surfaces (e.g., bearing seats) meet strict tolerances (Rz 6.3 µm).

• Performance validation: Successful testing confirms reliability under high rotational stress.

These benefits position metal DMP as a transformative solution for compressor wheels, balancing performance gains with economic and operational efficiencies.

DMP Design Guide

View our comprehensive guide to understanding SLS design.