CNC machining services

It has been observed that there are 4 ways of manufacturing:

Moulding; (e.g. injection moulding, vacuum casting)

Forming; (e.g. car body panel pressing)

Cutting/machining, (e.g milling)

Layer manufacture; (e.g. 3D printing)

And of all of these, one of the most flexible and capable processes is the cutting and machining process known as CNC machining.

Whilst the process of marrying CAD data, cutting pathway software and servo controlled milling machines has been around since the 1980’s, there are advances in the technology every year, which we at Aben are constantly adopting.

The beauty of CNC machining is that the CNC machine is effectively driven directly from your CAD model, and so the danger of human interpretation error of a drawing is removed. Complex geometries can be achieved with ease, and our typical feature accuracy is better than 50 microns.

Aben has a policy of continual renewal of the CNC machinery and software used to make our customer’s parts. We have the capability to precisely manufacture your requirements on demand. This type of Computer-Aided Manufacturing (CAM) has ushered in a realm of limitless possibilities.

We typically quote within 24 hours, enabling you to make fast decisions concerning your project, and we offer some of the fastest turn-around times in our industry. This coupled with reliable delivery makes us the best partner for your machining project.

If you require assistance with your CNC project, don’t hesitate to ask. Our highly experienced and knowledgeable staff have thousands of hours experience in hundreds of projects, and can advise on design, the types of finish and material you may require, and any post machining processes which could be useful, such as hardening or metal surface finishing.

Be assured that you will always receive our closest attention. We pride ourselves on our customer service, as we do with our competitive pricing and our reliable delivery. We know that the only way that we can succeed is if you succeed.

Quality Assurance System

We strongly believe in value for money. We believe that good quality does not mean ‘ultra-high precision’, but means that a part meets and exceeds all of your specification but at a price which reflects the effort which has gone into making it.

When you design and specify a part, please consider carefully such aspects as tolerance requirements, surface finish and the material properties you need. Judicious choices of these factors will lead to a part which meets all of your performance requirements, but at the lowest cost.

Once the part is made, you will want assurance the part meets your specification. This is where our QA procedure becomes an important part of our service.

We ensure that the part meets your specification. We have the capability of measuring a wide variety of part parameters, such as feature sizes, hardness, surface composition and many more. If you have a specific dimension / feature concern, please identify with your quote request. We normally retain this information here, but if required, we can issue QA documentation such as:

Dimension reports

Materials certificates

Certificates of Conformity

First article inspection reports

We pride ourselves on the quality of our CNC components and we know you will find them satisfactory.

Materials for CNC

Aben Europe can supply a wide variety of materials for you every need. Included in our standard range are ferrous, non-ferrous, plastics and specialize in foam.

Ferrous Materials

Ferrous materials are dominated by steels, which are graded into four groups, carbon steels, alloy steels, stainless steels and tool steels.

Carbon steels

Besides carbon and iron, carbon steels contain only trace amounts of other components. Carbon steels are the most common of the four steel grades, accounting for 90% of total steel production! Carbon steel is classified into three subgroups based on the amount of carbon in the metal:

Low carbon steels/mild steels (up to 0.3% carbon)

Medium carbon steels (0.3–0.6% carbon)

High carbon steels (more than 0.6% carbon)

Companies frequently produce these steels in large quantities since they are relatively inexpensive and robust

Alloy Steels

Alloy steels are made by the combination of steel with additional alloying elements such as nickel, copper, chromium and/or aluminium. Combining these elements improves the strength, ductility, corrosion resistance and machinability of the steel.

Stainless Steel

Stainless steel grades are alloyed with 10–20% chromium as well as nickel, silicon, manganese, and carbon. These steels have phenomenally high corrosion/ rust resistance and find uses in applications whereby manufactured items are used in a corrosive environment. Stainless steel grades are also commonly used in electrical devices.

Tool Steels

Tool steels include materials such as tungsten, molybdenum, cobalt and vanadium which provide heat resistance and general durability. They can usually be surface or though hardened, and are consequently used in applications where high hardness and durability are essential, such as for high production injection mould tools, and for cutting and stamping tools.

Commonly Available Steels

Aben has a wide array of steels available for manufacture. The commonest steels which our customers use are listed below, however, many other varieties are available, and so if you do not see the grade you require listed here, please contact us.

| TYPE | BS Number | EN Steel No. | AISI/SAE Grade |

|---|---|---|---|

| Carbon Steel | EN3B | 1.0402 | 1020 |

| EN8 | 1.0511 | 1040 | |

| EN9 | 1.0535 | 1050 | |

| EN19 | 1.7225 | 4142 | |

| Alloy Steel | EN24 | 1.6582 | 4340 |

| EN31 | 1.3505 | 52100 | |

| En36 | 1.5752 | 1.5752 | |

| Stainless Steel | 304S 11 | 1.4306 | 304L |

| 316 | 1.4436 | 316 | |

| 316S 11 | 1.4404 | 316L | |

| 430 S17 | 1.4016 | 430 | |

| Tool Steel | BO1 | 1.251 | O-1 |

| BH13 | |||

| BD2 | 1.2379 | D-2 |

Non-ferrous materials

Aben Europe can supply a wide range of Non-ferrous materials, amongts the materials which are readily available are:

Aluminium

Titanium Ti-6Al-4V (TC4)

Bronze C510

Copper C101

Additionally we have access to other Non-ferrous materials, click here to see more.

Below we list the grades of aluminium which are the most commonly purchased by our customers.

| ANSI-AA | DIN | EN Numbers | ISO Reference. | British Standard | UNS |

|---|---|---|---|---|---|

| AA 6082 | 3.2315 | EN AW-6082 | Al-Si1Mg | H30 | A96082 |

| AA 6060 | 3.3206 | EN AW-6060 | Al-MgSi | H9 | A96060 |

| AA 6061 | 3.3211 | EN AW-6061 | Al-Mg1SiCu | H20 | A96061 |

| AA 7075 | 3.4365 | EN AW-7075 | Al-Zn6MgCu | 2L95 | A97075 |

Plastics – available in a variety of colours

Aben Europe can supply a wide range of Plastic Polymers in a variety of colours, mechanical and thermal properties to satisfy most customer requirements. Amongts the materials which are readily available are:

ABS

POM

Nylon

PEEK

Above are a sample of typical plastic materials we have machined, if you have a specific material not listed, please let us know when you request a quotation.

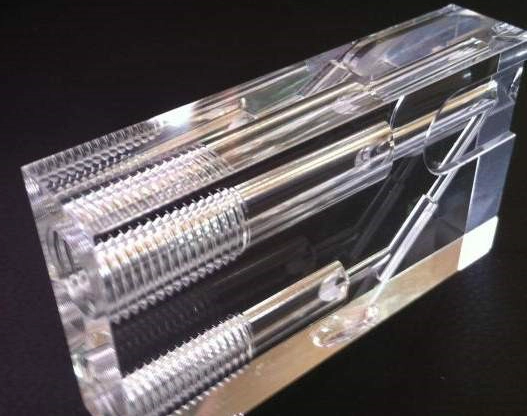

Most materials can be machined to various surface finishes, even a polished clear finish is available with materials like Acrylic and Polycarbonate. We can provide a range of post-machining processes such as painting, screen printing, laser engraving, metal plating and assembly.

We are here to support your plastic CNC needs, both small volume and big batch, from prototype to on-going production.

If the material you require is not listed here, please contact us as we can source other materials as well.

Finishing Options

We can supply parts with a wide range of surface finishes. These include:

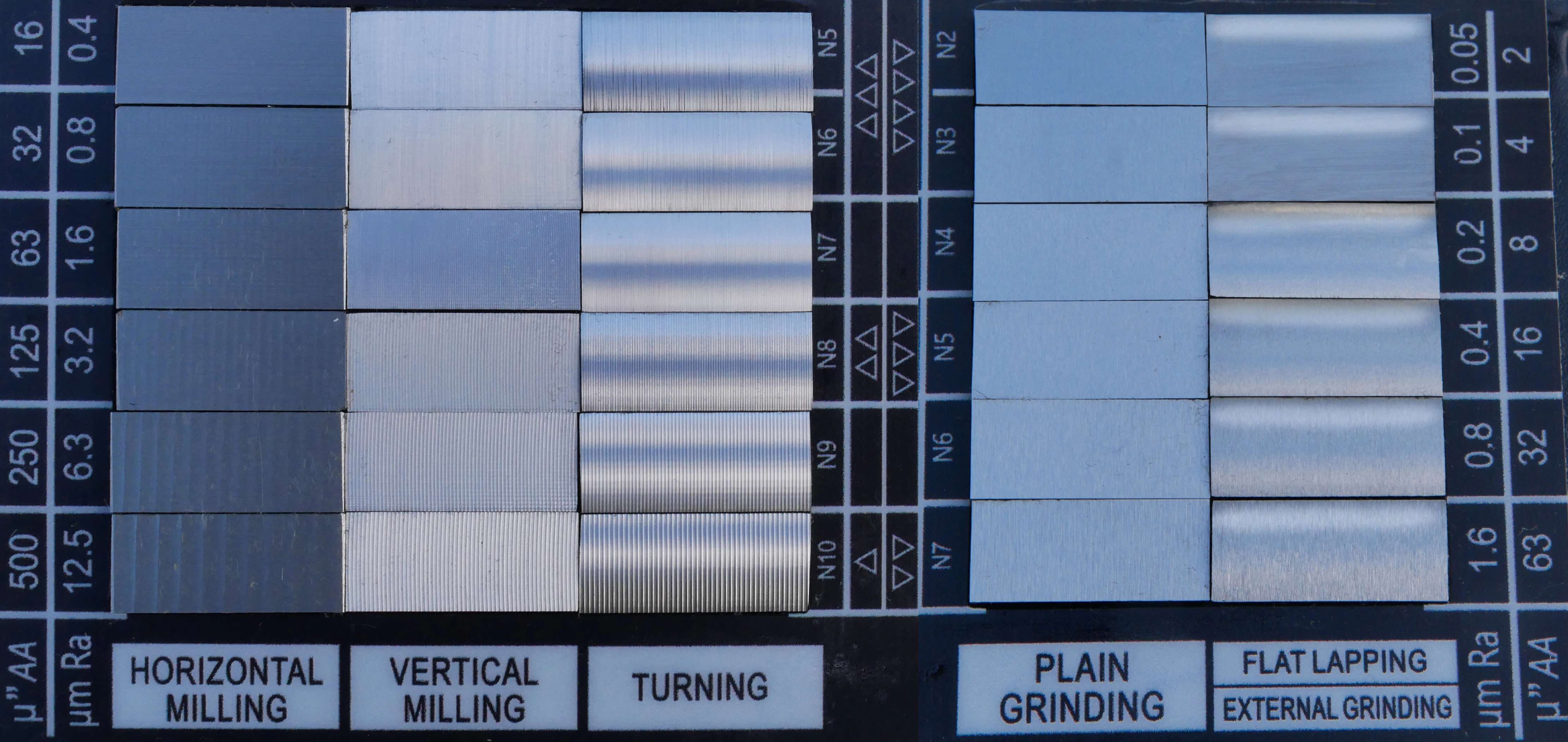

As Machined: Surface texture can be designated by specifying the Ra value, with Ra3.2 - 1.6um being the standard. We can supply parts with finer finishes, down to a polish. As costs increase with the smoothness of the final surface finish, it is important to specify the appropriate finish for your application.

Bead Blast: Standard bead blast size: 80um. Options available from 50-120um.

Anodised Type II: Standard Options: Clear/natural, black, red, green, blue, yellow/gold. Close matching to specified RAL numbers.

Anodised Type III: Standard Options: Black or Grey. Although it has a less glossy appearance, it provides superior surface protection.

Machining for Prototyping

We know the importance of prototyping parts before you embark upon your main production. Whilst 3D printing can be very useful for many of ‘fit and form’ design verification applications, sometimes only the correct ‘target’ material will do for your prototype part.

Aben Europe will support you all the way through your development programme. We are capable, and very willing to supply ‘one off’ components, all the way to the numbers you need for small and medium volume production runs. We pride ourselves in keeping our prices competitive throughout.

If you want to know how competitive – simply ask us for a quote

Technical Ceramics

Technical Ceramics, also known as Engineering Ceramics, are used in high-technology applications, such as aerospace, high power electronics and other demanding industries.

Engineering ceramics provides the types of functionality which metals and polymers can not. These include:

Strength

Hardness

Wear-resistance

Maintain their properties at very high temperatures (up to 1,760 °C)

Excellent thermal insulation

Excellent electrical insulation

Oxidation-resistance

Very Chemically stable

ABEN Europe provides a bespoke high precision technical ceramic machining service, producing components by 3 axis CNC milling and turning.Materials which are provided include Aluminium Oxide, Zirconium Oxide, Silicon Nitride, Aluminium Nitride, Silicone Carbide, and Machinable Ceramic Components, etc.

The table below lists some of the materials which are available along with some of their properties.

| Properties | Units | Cordierite Ceramic | Mullite Ceramic | 95% Alumina Ceramic | 96% Alumina Ceramic | 99% Alumina Ceramic | 99.5% Alumina Ceramic | 99.7% Alumina Ceramic | Silicon Nitride | Zirconia Ceramic | Macor Ceramic |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Colour | Yellow | White | White | White | Light Yellow | Light Yellow | Light Yellow | Black | White | White | |

| Density | g/cm3 | 1.9 | 2.6 | 3.6 | 3.7 | 3.8 | 3.8 | 3.9 | 3.2 | 6 | 2.5 |

| Flexural Strength | MPa | 30 | 120 | 300 | 320 | 350 | 375 | 375 | 800 | 1100 | >94 |

| Compressive Strength | MPa | 350 | 500 | 2000-2500 | 2000-4000 | 2800 | 2800 | 2554 | 2600 | 3000 | >345 |

| Modulus of Elasticity 20C | GPa | 40 | 100 | 300 | 320 | 350 | 350 | 357 | 290 | 320 | 65 |

| Max Use Temperature | °C | 1200 | 1300 | 1400 | 1500 | 1500 | 1500 | 1760 | 1300 | 1050 | 1000 |

| Thermal Conductivity | W(m.K) | 1.3-1.8 | 2~6 | 20 | 24 | 30 | 30 | 33-38 | 25 | 3 | 1.48 |

| Thermal Expansion Coefficient | 10-6/°C | 2.5-3.0 | 2.5-3 | 7.5 | 7-8 | 8 | 8.2 | 8.2 | 3 | 10 | 7.2 |

| Thermal Shock Resistance | ΔT°C | 300 | 150 | 140 | 150 | 150 | 200 | 223 | 600 | 250 | 25-100 |

| Dielectric Strength | KV/mm | - | - | 15 | 15 | 18 | 18 | 23.4 | 14 | 15 | >40 |

| Dielectric Constant | Er | 8 | 8 | 9 | 9.2 | 9.2 | 9.2 | 9.84 | 9 | 26 | 5.9-6.3 |

Utilising ABEN Core Competitive Advantages

ABEN’s “core competitive advantage” is that we can provide one stop service of ceramic structural parts used in the fields of high temperature, semiconductor, pumps and valves, new energy, fluid controlling, machinery wearable parts, etc.

We have also integrated a variety of advanced ceramic resources, we select the most suitable engineering solution according to different custom made parts and technical demands. One side the product quality could be more easily controlled comparatively, the other side the costs are also saved for the customer. Offering the idea solution for customer’s different application demands, no matter whether it is on cost or engineering solution, our aim is to find the most reasonable way for customer.

Manufacturing Capabilities

ABEN Europe offer manufacturing equipped with advanced ceramic forming, sintering and machining machinery which covering isostatic pressing, injection moulding, dry pressing and sintering furnace. Machining wise, we offer internal & external grinding, centerless grinding, flap grinding, CNC machining, polishing, laser cutting and honing machine.

If you want to know how competitive – simply ask us for a quote

CNC Design Guide

View our comprehensive guide to understanding the limitations of CNC machining.

Quoting Process

1

ENTER CONTACT DETAILS

2

SPECIFY MATERIALS, TOLERANCES & FINISHES

3

SELECT RELATED FILES

4

UPLOAD FILES