Aben low volume manufacturing services offer a range of key features and capabilities to effectively meet the needs of its clients. These features ensure that our services can deliver high-quality, customized components or assemblies efficiently and cost-effectively. Here are the essential low volume manufacturing offerings we can provide:

Customisation and Flexibility

Manufacturing Technologies

CNC Machining: Our CNC machining offers a precision solution for producing complex parts with high accuracy.

3D Printing: Additive manufacturing can often be used for low volume production of small to medium sized parts, very economically. It offers the additional benefit that ‘light-weighting’ is easily achievable, and it can produce geometries which are almost impossible to develop by traditional subtractive techniques.

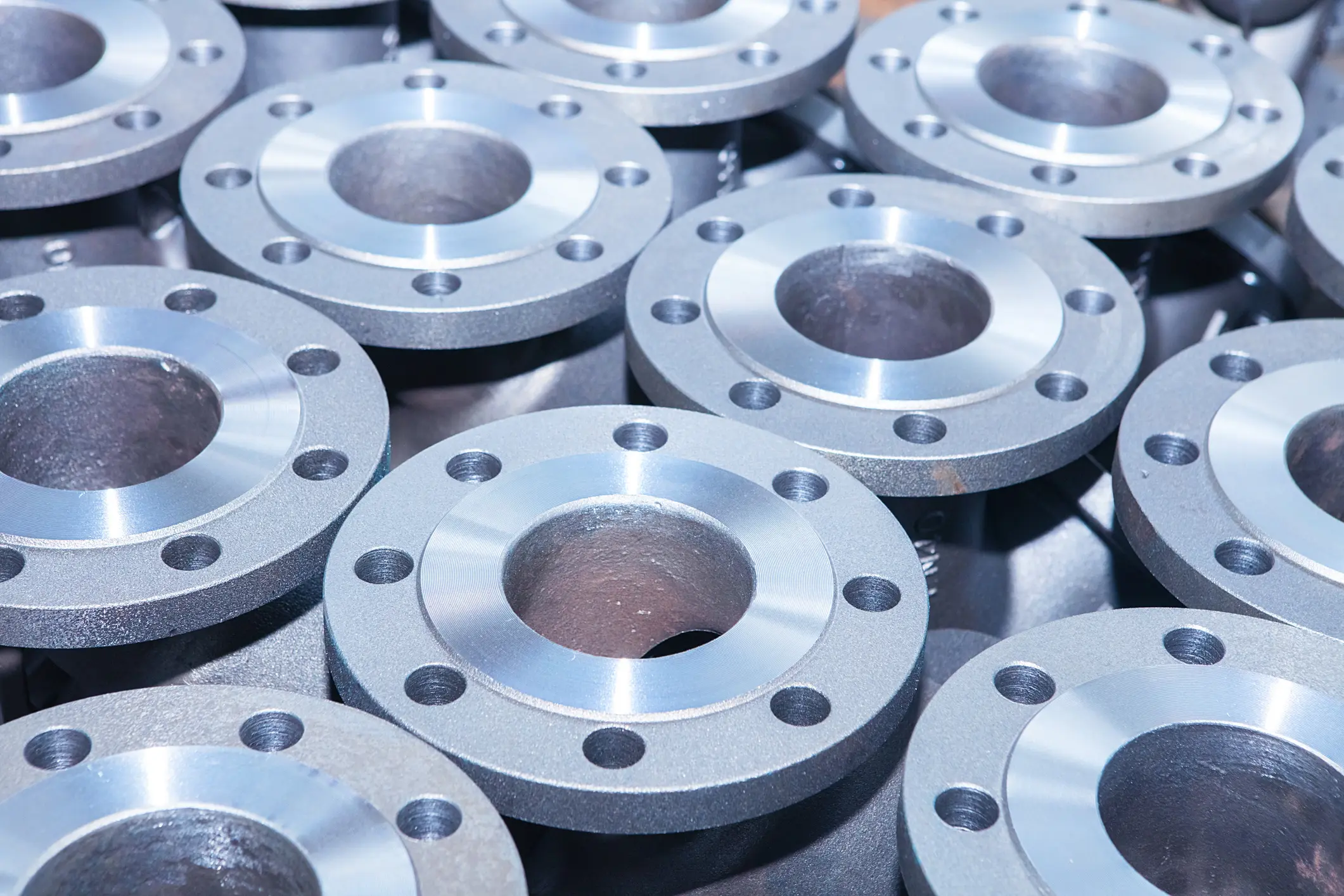

Precision Investment and Die Casting: We offer high-quality casting methods for producing durable and detailed components at very low prices in a variety of metals. Castings can be post-machined and then finished by a variety of processes such as sand blasting or powder coating.

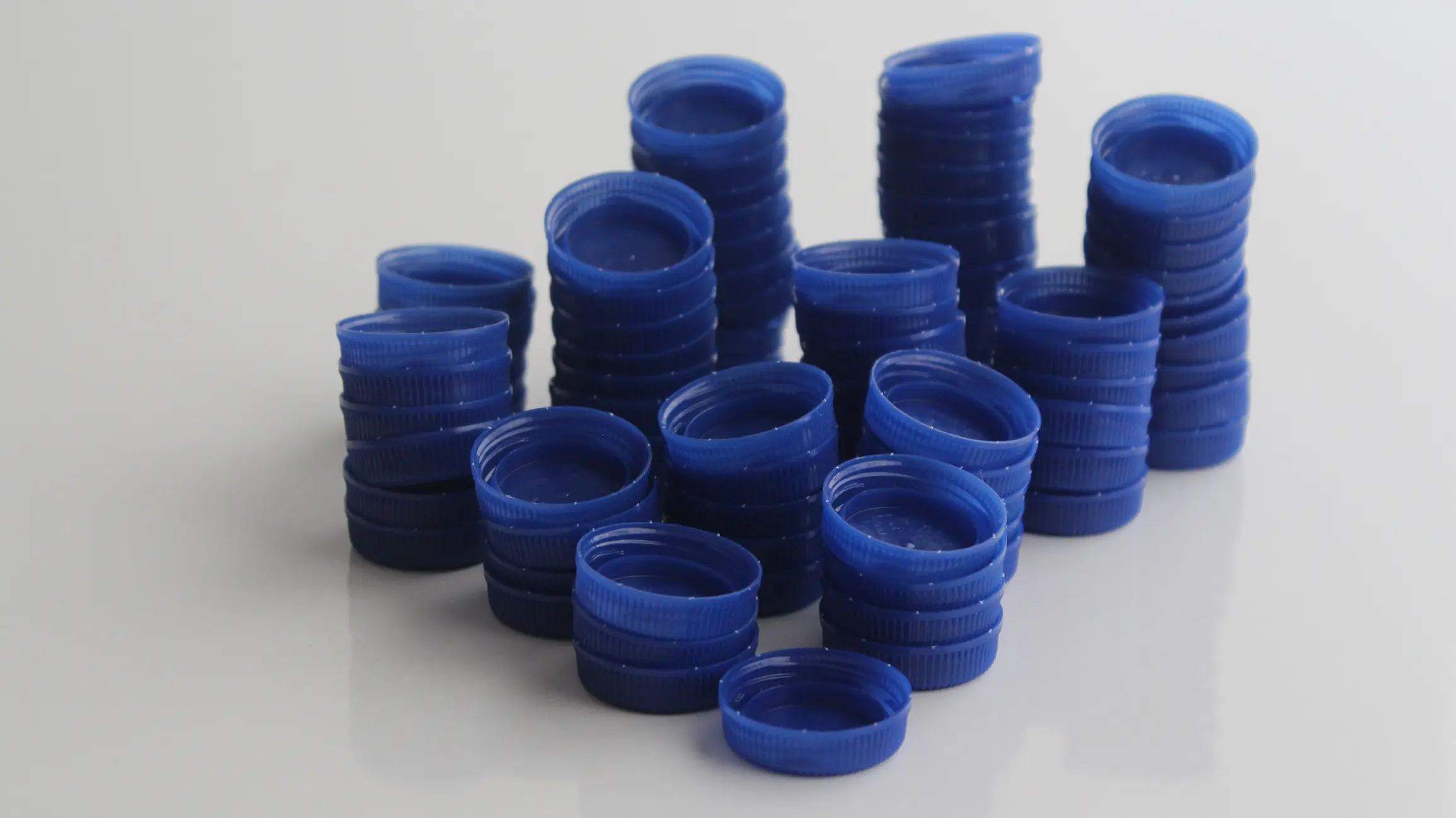

Vacuum casting: Our vacuum casting process enables the production of parts in numbers from 5 – 500 plus which have the look and feel of traditional injection mouldings. This process is extremely flexible, providing parts which can be rubber-like, or hard and glass clear or dyed to a wide range of RAL numbers. The process is excellent as a bridging method before full injection mould tooling becomes available.

Vacuum Forming: Is another relatively low cost technique for the production of excellent quality complex components. It has the added benefit of being capable of producing parts in a wide variety of sizes, from ‘matchbox’ to ‘engine bonnet’.

Injection Moulding: Aben staff have a great deal of experience with the production of low volume runs of injection mouldings. We have supplied to such industries as automotive, producers of PPE, the electronics industry and many others.

Rapid Prototyping

Quality Assurance

Rigorous Testing: Quality assurance is a key part to high quality low volume manufacturing where techniques such as Statistical Process Control cannot be used to adequately control final part quality. Our comprehensive testing and inspection processes ensure each component meets your exact specifications.

Comprehensive Quality Control: We use modern techniques to control our manufacturing processes based on the feedback of QC reports to help guarantee quality and reliability.

Cost Efficiency

Low Tooling Costs: To be profitable, low volume manufacturing requires tooling suitable for the numbers to be manufactured. Whilst producing parts to the highest quality, our low volume tooling is relatively low cost, requiring reduced initial investment, compared to high volume manufacturing and there reducing the time to profitability.

Resource Optimization: We are constantly seeking ways to make the most efficient use of materials and resources to minimize waste and control costs.

Skilled Workforce

Expert Engineers: Our experienced engineers and technicians which will support your project can provide valuable insights and ensure high-quality production.

Customer Support: The Aben dedicated support teams will assist you throughout the manufacturing process, from design to delivery.

Scalability

Supply Chain Management

Sourcing and Logistics: Efficient management of supply chains to ensure timely procurement of materials and delivery of finished products.

Inventory Control: Effective inventory management to balance supply and demand, reducing lead times and costs.

Sustainability

Eco-Friendly Practices: We are strong believers that we should always be seeking practical methods to implement sustainable manufacturing practices to minimize environmental impact.

Material Efficiency: We constantly look for ways to recommend to our clients advanced materials and processes to reduce waste and improve sustainability.

Comprehensive Services

Manufacturing method support: We have worked on many projects for a wide range of industries and have a great deal of experience of low volume manufacturing. If required, we can offer advice about the types of manufacturing process which your project requires, and the most efficient way to implement it.

Design for Manufacture Support: We can provide recommendations to component design which will reduce manufacturing costs and aid performance.

Post-Production Services: Offering additional services such as assembly, finishing, and packaging to provide complete solutions.

Conclusion

We offer a wide range of low volume manufacturing services to add value to your project. We provide high quality components and can provide these at attractive prices, which will significantly add value to your project. We can help bring your innovative products to market quickly and efficiently while maintaining high standards of quality and customization.

To learn more about low volume manufacturing, read our guide ‘Benefits of Low Volume manufactuirng’ available to download below.

If you have a project you’d like to disucss, please contact us by telephone or email. Our details are on our contact page here.

Request a Quote

To start your own Low Volume Manufacturing quote please follow the link below, or fill in our Request a quote form below.