What is Vacuum Casting?

Vacuum casting is a rapid prototyping technology that allows the manufacture of many plastic parts (even with the presence of the undercuts) from a master model. The parts obtained are suitable for assembly testing. This process uses the vacuum effect to inject the material into a silicone mould (hence the alternative names “silicone moulding” and “vacuum casting”). The injected materials are polyurethanes who’s Shore (hardness) can be adjusted. Therefore, unlike other technologies, it allows the creation of flexible parts.

Vacuum casting uses a master model produced with 3D printing, stereolithography or CNC machining to obtain a silicone mould. This mould makes it possible to obtain many parts in a Polyurethane material which mimics and is close to the final material, making vacuum casting perfect for pre-production or low volume production.

The Aben on line quoting tool does not yet produce vacuum casting quotes and so to obtain a price for your vacuum casting requirements please contact quotes@abeneuope.co.uk with any data you have and a description of the type and number of parts you require, and we will reply as soon as possible.

The applications

The parts obtained by vacuum casting are suitable for functional and visual testing. Indeed, the physical, mechanical, thermal and aesthetic qualities of the parts created are very similar to those of injection moulded parts. This is explained by a large number of available resins that offer a wide range of possibilities. For example, the material can be transparent, can imitate a fibre reinforced, be of different harnesses, or reproduce the properties of ABS, PMMA, PC, PE, PP, etc. We can apply various finishes, such as glossy finishing or soft touch and can simulate several applications such as overmoulding of inserts.

The advantages of vacuum casting

- High precision, fine detail: the silicone mould makes it possible to obtain parts totally faithful to the original model, even with the most complex geometries. The result is perfect, with quality comparable to the final part.

- Quality of the part: the use of resins allows you to choose a material as close as possible to the right material, with a wide choice of harnesses: flexible or rigid, but also the final appearance: the part can be coloured in the mass or else have a ‘crystal’ type transparency. It is also possible to create overmoulding (for example with brass inserts) and produce painted finishes.

- Prices and deadlines: the use of silicone for the mould allows a reduction of costs compared to an aluminium or steel moulds. In addition, you can achieve economies of scale from around ten parts, which makes this method more valuable than 3D printing. Finally, it takes typically 15 to 20 days to get 30 to 50 functional prototype parts, making it an attractive method to meet urgent needs.

The limits of vacuum casting

- The lifetime of the mould: the silicone mould has a shorter lifetime than an injection mould, and the tool thus created can produce only a few dozen parts.

- Installation: due to the need to have an original model and create a silicone mould, this method requires a small investment, in contrast to 3D printing or stereolithography. Nevertheless, this investment becomes an advantage thanks to economies of scale as soon as more than 5 to 10 parts have to be produced.

The preferred uses of vacuum casting

For all the reasons mentioned above, vacuum casting is recommended for:

- Pre-production to test the market with your customers

- Pre-production for certification

- Pre-production for mechanical or aesthetic validation in marketing and design

- Small series for the first commercialization

- Low volume production

The method

The procedure of vacuum casting is a type of low-pressure vacuum injection manufacturing or vacuum duplication. It involves injecting material into a pre-prepared silicone mould. This technique makes it possible to obtain multiple parts from a single mould. It, therefore, results in significant economies of scale. However, one mould can be used a limited number of times. This depends on the quality of the mould and the geometry of the parts.

Finally, the use of the vacuum machine makes it possible to remove air from the material and prevent the formation of air bubbles that would make the parts fragile.

The way it works

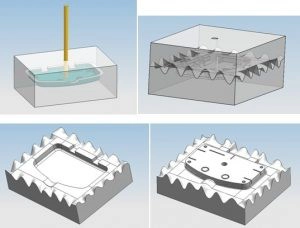

In the first step, a master is produced and put into a box, which the silicone is poured into to make the mould. In the second step, the cavity of this silicone mould is filled using polyurethane resins by means of a specific vacuum casting machine to obtain the desired parts.

First step: creating the silicone mould

- A master part is made by stereolithography, 3D printing or CNC machining

- This master part is placed in a box in which liquid silicone resin is poured

- Once the silicone has cured, the silicone is cut along the separation line, and the master part is removed from the mould

Second step: production of series parts

- Once the silicone mould is placed in the machine, the selected material is then injected under a vacuum

- The tool is then cooled, the mould is then opened to remove the finished part

Once the parts have been produced, it is possible to add finishes such as over-moulding and additions of inserts, painting, printing etc.

Quoting Process

1

ENTER CONTACT DETAILS

2

SPECIFY MATERIALS, TOLERANCES & FINISHES

3

SELECT RELATED FILES

4

UPLOAD FILES