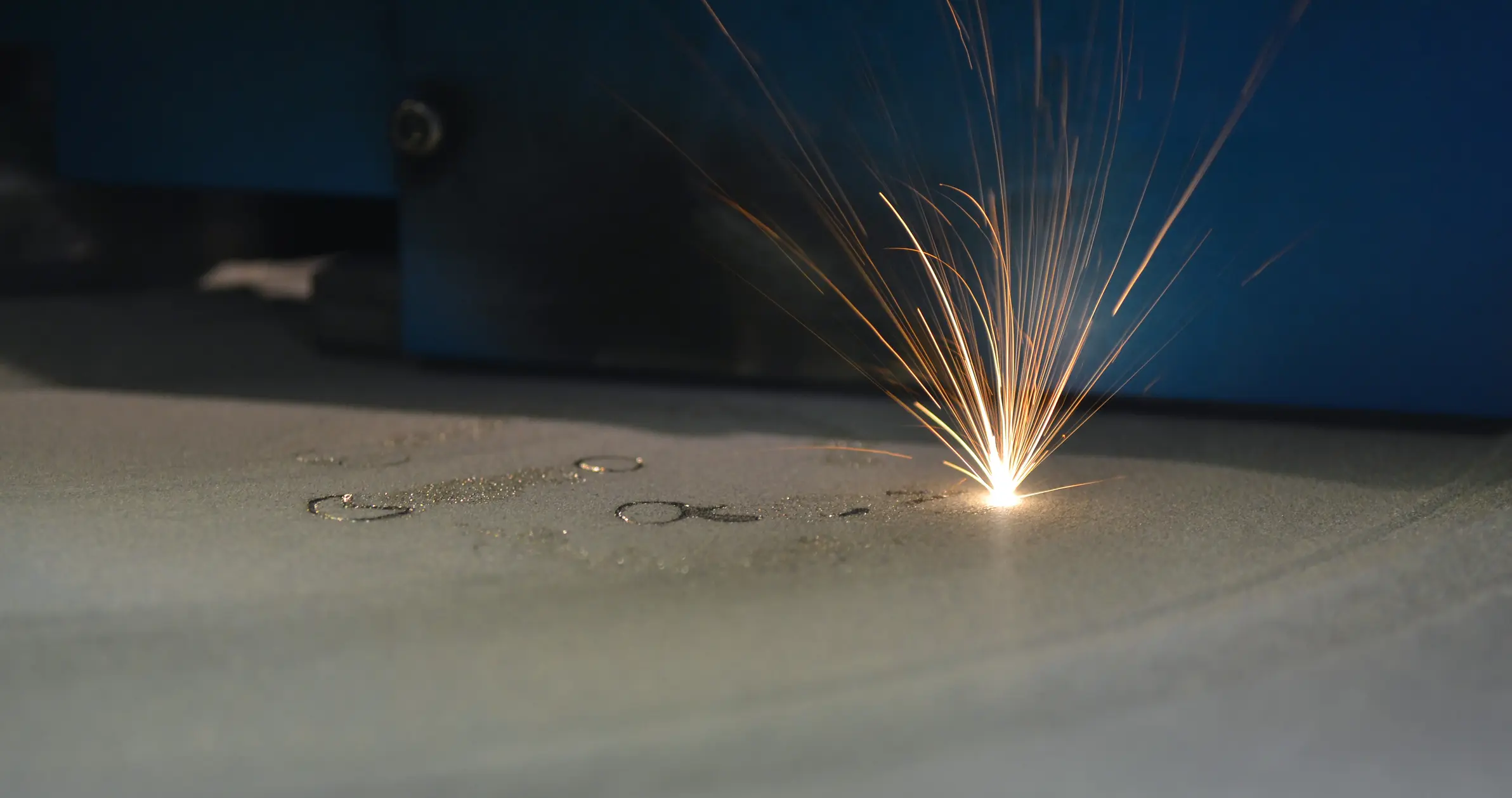

Design Guide for 3D Metal Printing

Designing for metal 3D printing requires specialized strategies to leverage its advantages while avoiding manufacturing defects. Key principles include optimizing part orientation, minimizing supports, and accommodating post-processing needs. Below is a structured guide synthesizing industry best practices.

Key Design Principles

1) Part Orientation and Critical Dimensions

• Orient critical dimensions parallel to the build plate for higher precision, as the print head achieves better accuracy on the XY plane than along the Z-axis.

• Prioritise flat, stable surfaces on the build plate to prevent toppling during sintering and reduce support needs.

• Unlike polymer printing, anisotropy is less critical in metal due to powder fusion during sintering, so strength-based orientation is secondary.

2) Minimizing Supports

• Use chamfers (≥45°) or fillets on edges to reduce overhangs, cutting support material by up to 30% and speeding up post-processing.

• Ensure supports are accessible for removal with hand tools; avoid complex internal geometries that trap supports.

• For holes not aligned with the build direction, use teardrop shapes instead of circles to eliminate support structures.

3) Hollow Structures and Powder Removal

• Include at least one escape hole (≥3mm diameter) in hollow designs to remove trapped powder.

• Complex cavities require multiple holes (≥7mm) to prevent powder traps, with central placements being optimal.

• Avoid unsupported horizontal edges exceeding 0.5mm (DMLS/SLM) or 20mm (Binder Jetting); add 45° chamfers for stability.

Material-Specific Guidelines

Stainless Steel (SS316L) Best Practices:

• Wall Thickness: Minimum 1mm (Standard Grade) or 0.5mm (Performance Grade), but 2mm is recommended for structural integrity.

• Details: Embossed/engraved text should use Arial 20pt with 0.4mm height/depth for readability.

• Thermal Stress Management:

o Apply fillets (≥3mm radius) to edges and avoid sharp corners to reduce stress-induced warping.

o Prefer organic shapes over blocky designs to distribute heat evenly.

Design Rules by Process

Critical thresholds vary by technology. Below are key limits:

| Model 'A' SurfaceParameter | DMP |

|---|---|

| Min. Wall Thickness | 0.4 mm |

| Max. Aspect Ratio | 8:1 |

| Min. Hole Diameter | 1.5 mm |

| Max. Overhang Angle | 50° |

Advanced Optimisation

• Batch Processing: Pack multiple parts in a single sintering run to lower per-part costs.

• Inner Channels: Use teardrop-shaped profiles (minimum 3.5mm) instead of cylinders to avoid supports.

• Volume Reduction: Strategically hollow non-critical sections to cut material use and costs without compromising strength.

Post-Processing Considerations

• All metal 3D-printed parts require post-processing (e.g., support removal, sandblasting or CNC machining for tight tolerances).

• Design for machinability: Close holes needing high precision and machine them post-print.

By integrating these principles—prioritizing orientation, minimizing supports, and designing for manufacturability—engineers can fully harness metal 3D printing’s potential for complex, high-performance parts.